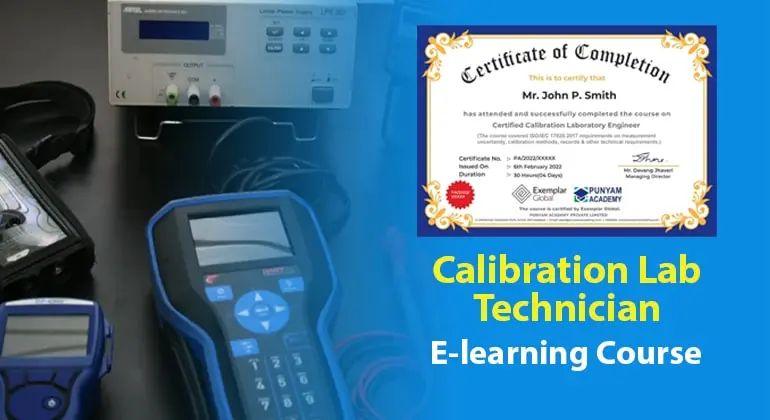

Certified Calibration Laboratory Technician

PAC05 Type: E-Learning

Description

In general, the responsibility of the instrument technician is to follow the proper calibration procedures to accurately calibrate the instrument. The term “Calibration” is defined as a test during which known values of measure and are applied to the transducer and corresponding output readings are recorded under specified conditions. Select one of our Instrument Calibration Courses, and get the basic knowledge of calibration such as Requirements of calibration, technical requirements and calibration method for relevant instruments.

Punyam Academy’s this Certified Instruments Calibration Technician Training course has been designed to introduce participants or users to the basic principles of calibration instruments. With the newly developed Online Course – Instruments Calibration Training user get knowledge of preparing calibration certificates and work sheets for types of equipment, Metrological, Mechanical, thermal & electro technical, etc.

TOPICS COVERED UNDER CERTIFIED INSTRUMENTS CALIBRATION ENGINEER TRAINING COURSE

Following 4 sections are comprised by The Certified Instruments Calibration Technician online training:

- Lectures

There are total 21 lecture sessions in this course. The lectures are provided with visual ppt presentation with explanatory audio to understand the subject well. Following are the sessions:- Session – 1: What is calibration?

- Session – 1: Uncertainty of Measurement

- Session – 3: Calibration Method and Records for Caliper

- Session – 4: Calibration Method and Records for Height Gauge

- Session – 5: Calibration Method and Records for External Micrometer

- Session – 6: Calibration Method and Records for Plain Plug Gauge

- Session – 7: Calibration Method and Records for Dial Indicator

- Session - 8: Calibration Method and Records for Vacuum Gauge

- Session - 9: Calibration Method and Records for Pressure Gauge

- Session - 10: Calibration Method and Records for Weighing Balance

- Session - 11: Calibration Method and Records for Weight

- Session - 12: Calibration Method and Records for Tachometer

- Session - 13: Calibration Method and Records for Infrared Thermometer

- Session - 14: Calibration Method and Records for Thermo Hygrometer

- Session - 15: Calibration Method and Records for Oven

- Session - 16: Calibration Method and Records for Glass Thermometer

- Session - 17: Calibration Method and Records for Controller with Sensor

- Session - 18: Calibration Method and Records for Multimeter

- Session - 19: Calibration Method and Records for Temperature Controller

- Session - 20: Calibration Method and Records for Energy Meter

- Session - 21: Calibration Method and Records for Clamp Meter

- Hand-outs

For all the above 21 topics, the hand-outs in more than 300 pages is given in pdf format. The participant of this Instrument Calibration Training E-learning course can download and save those particular hand-outs in their computer and print it or read it offline to get detailed knowledge of all the 21 topics given above. - Exams

In this online course, a total 21 session exams and one final exam are given. After passing all the exams, the participants will be awarded the Certified Instruments Calibration Technician Training Certificate and can download and print their training certificate. - Video Presentation

The complete calibration demonstration videos of actual calibration are provided under this section. Calibration Technician can view and learn how to perform calibration and maintain the quality of the instrument calibration process.

COURSE OBJECTIVES

After completion of this Certified Instruments Calibration Technician - E-learning course, you will be able to:

- Basic knowledge of calibration such as Requirements of calibration, why do we need calibration, equipment selection, Types of equipment, Metrological, Mechanical, thermal & electro technical traceability, selection of calibration agency etc.

- Understand the requirement of ISO/IEC 17025:2017 requirements for measurement uncertainty

- Understand the theory of uncertainty of measurement, selection of uncertainty measurement factors, and calculation of measurement uncertainty.

- Understand the relevance of instrument measurement, including the use of an instrument.

- Understand technical requirements and calibration methods for relevant instruments.

- Preparation of calibration certificates and worksheet.

WHO SHOULD ATTEND THIS COURSE?

This e-learning course is designed for:

- Professionals and management in measurement or related roles

- Metrology managers

- Quality managers

- Quality engineers

- Calibration engineers

- Manufacturing engineers

- Co-ordinate measurement users and programmers

- Metrologists

- Professionals working in inspection departments

- Students, apprentices and graduate engineers

- Wider audience (with interest in dimensional measurement).

AUTHORS & INSTRUCTORS

For details of the authors, trainers and instructors experience and background, please visit our trainers page. They have very rich experience on the subject.

STUDY MATERIALS

This e-Learning course is provided with study materials and you can read it after your log in or download (PDF format). Use the study materials to reinforce key points and to keep a reminder of what you already learned as well as you can save it in your computer for future reference. The access of this study material is removed after exam is cleared and on line certificate is prepared for the student.

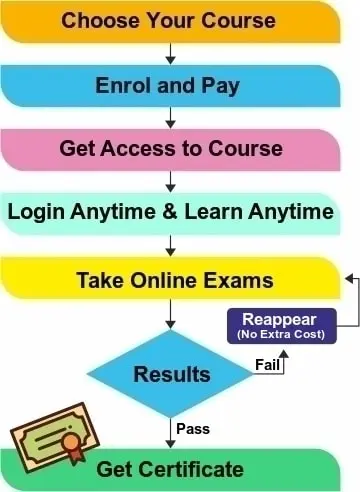

EXAMINATION AND COURSE CERTIFICATE

All paid E-learning course includes the Course Certificate that is issued upon course completion and passing the session exams as well as a final exam given in the course with minimum 60% marks. The option to reappear in the exam is also given to student, if failed in any exam.

END OF COURSE INSTRUCTION

After completing the session and passing each session examination the student can appear for final exam. Once the final exam is cleared then it is considered a end of course. The training certificate is ready on our LMS and student can print it or save the training certificate. It is also available for verification by entering the name and certificate number.

- Duration30 Hours (04 Days)

- Price (USD) $499

- DOWNLOAD COURSE DEMO

- TypeE-Learning

- LanguageEnglish

Search Course

Why Learn with us?

How Automated LMS Works?